Innovation of Metal

ひんやりとした鉄に熱い思いを込めて

Words by Kenji Jinnouchi, Photographs by Hiroshi Mizusaki,Edit by Masafumi Tada

Kaoru Shimizu, the director of EXIT METAL WORK SUPPLY moved his factory to Onojo, Fukuoka, from Tokyo in December 2012.

They specialize in iron furniture such as; metal hanger racks and shelves mainly for clothes retailers, and offer beautifully stylish products which feature a very original iron texture on them. These products have made a lot of famous fashion brand companies inside and outside of Japan fall in love.

Why did this company leave Tokyo?

“We wanted to stay close to the best coating company in Japan, who operates their business from Onojo,” says Shimizu.

CENTRAL FEATURE#3 has turned out to be an in-depth interview with Kaoru Shimizu and Kouki Hashimoto, the executive director of Tokiwa Tosou, whose company is trusted by Shimizu as “the best coating company in Japan”. This would be a must-read for all of the colleagues in the same industry; leaking out their business tips and secrets.

C: First of all, would you tell us why you and your company moved to Fukuoka?

Shimizu: It’s because we needed the best work network. I was born and raised in the Shitamachi area of Tokyo. As a teenager, I started working at one of the metal work factories there. There used to be so many town factories of plating and coating in the area as well. We made metal products and had them coated. Recently, within the last 5 years, there is a lack of these town factories. I think some reasons are young workers are getting less enthusiastic, and the experienced workers may be finding it difficult to find acceptable candidates to take over their business.

It was difficult to maintain the high quality of work in the area, which generated negative feedback and complaints were becoming a big problem because of this. The spirit and atmosphere that was once positive seemed to be lacking. On the other hand, Higashi Osaka and Onojo seemed to be other prospective ‘hot spots’ for the metal furniture industry that the Shitamachi area had been known for.

Fukuoka is one of the top 3 places for the apparel industry in Japan, besides Tokyo and Osaka. These cities have also developed the industry of metal furniture accordingly in their neighborhoods. In Tokyo, these are Koto ward and Edogawa ward. In Osaka, it’s Higashi-Osaka, and in Fukuoka; Onojo.

C:Why has Onojo become a hot spot?

Hashimoto: Because it has good access to Dazaifu, where the highway interchange is. It is also a very convenient transferring location for products to Fukuoka or other cities in Japan. Originally, Okawa has been very successful in the woodworking industry as one of top furniture making places in Japan. It is said that the metal furniture business has also grown correspondingly in the same prefecture. The first metal work company in Onojo started their business 50 years ago, and now, there are increasingly roughly 100 factories and companies related to the industry.

C: Wow! Sounds like there are so many factories in one spot, but do they all take care of metal furniture?

H: No. I mean about 10 are similar to ours, who do baked coating. Out of those 10, only two are dealing with metal furniture.

There are two main reasons why there are few baked coating companies for metal furniture:

First, mass-producing one tiny metal part costs less hours and makes more sense for doing the business, which most metal factories in Onojo do.

It usually takes us more time than average to make our products, because they are almost always customized orders. Especially when it comes to colors, for example, if a customer asks for an uncommon shade of red, we need to paint it 20-30 times to meet the color.

The second reason; business owners who need furnishings for their new stores give us orders that need to be filled ASAP.

S: There is a lot of pressure and next to no time when we are given “ASAP” types of jobs to do.

C: How much time are you usually given for those?

H: They are usually done the same day. For example, as soon as we receive a product from the factory, we paint it in the morning, and after the final touches, it reaches the customer the same evening.

S: Our peak operation months are February and March because of so many new retail shops opening. When I was in Tokyo, I was under the impression my company was the only one working late hours because, generally most town factories in Tokyo finish around 5 p.m. I had believed my company was the most enthusiastic for working in the industry, but I found Tokiwa Tosou was way tougher. When I visited them around midnight with our final work for that day, Hashimoto said to me, “Hey, did you finish for today? Good for you, we need to finish this by morning.” I was amazed with their dedication. This was the first time I thought “Kyushu guys are different in strength.”

H: Even though it doesn’t happen all the time, once our customer asks, we would like to do our best. We need to spend a lot of time on each order and use techniques to satisfy their requests. However, we love our jobs because we are having fun working on original ideas.

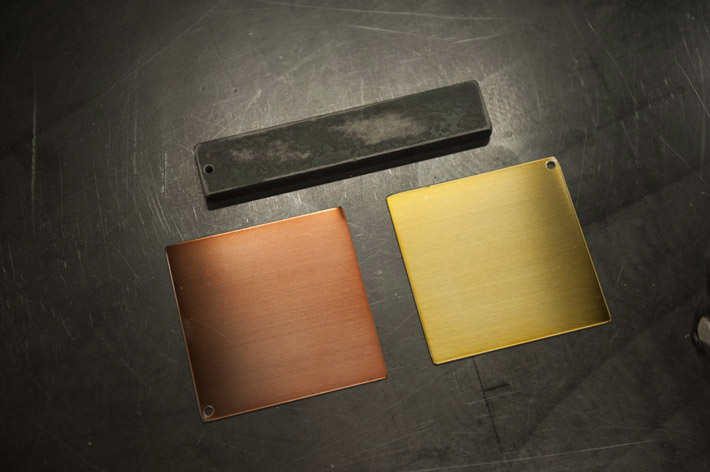

Here is a sample of color clear paint that I can show you, to make it in this kind of metallic color, plating used to be a popular process, soaking a product in the plating bath to color it like this. You can see that iron partition over there? (-I looked at it and it was huge!) It wouldn’t fit the bath, so in that case, each constituting part needs to be taken apart before getting into the plating bath. It takes a lot of work. However, we made it possible to paint the whole thing by spraying without taking it apart.

S: Yes. It definitely comes out a beautiful color in the end.

H: I started using color clear paint to fulfill the customers’ high needs. It’s been about 10 years since I finally became satisfied with what I had done, making it look plated by color clear painting.

S: That is the thing which had been my biggest concern for a long time when we were in Tokyo. The sample he showed you is actually a plate made of stainless steel, which color clear paint was applied to. It shines like real gold, doesn’t it? With regular spray paint, it can’t be like that. One day, when I was still in Tokyo, I complained to one company why the color is not painted evenly all over, and he said “It’s impossible.” and “it is not a big deal, is it?” I wasn’t impressed with their job, but I kind of understood what they told me.

After I visited Tokiwa Tosou in October, 2012, I felt quite shocked because he did the things that other companies said were impossible. And I learned that his company had received some orders from Louis Vuitton and Giorgio Armani. I had heard the rumor, “There is one person who does his job perfectly for any kind of order in this industry, and his company is in Onojo.” and I had been wondering who he was.

That was him. Two months after my first visit to Onojo, I moved here. However, I even felt I should have done it earlier. If I had known of him 5 years earlier, I think I could have done so much better on most products.

C: I know Onojo has good circumstances to learn more ideas since it is a hot spot, however, how did you expand your potential to reach the high quality and skills you have obtained?

H: In my opinion it’s because we repeated our trials and errors to meet customers’ requests. Speaking of color clear paint, it is not that easy to make a certain color and glitter like this sample. Usually, to make color clear paint, we needed to mix a color pigment with clear solution. However, it didn’t become a very transparent color with simple trials. First of all, I looked for appropriate pigment materials. I asked a supplier to try to find it or make one for us. Basically, they don’t mix pigments to make a certain color, however, they did take the time to make what we requested.

S: I am sometimes amazed at his curiosity and how smart he is! Maybe his experiences in the US have sharpened his way of thinking.

H: The largest obstacle that coating companies find with using color clear paint is that it doesn’t seem to bond very well with stainless metal, especially when it is polished to have a mirrored finish.

S: Coating companies in Tokyo would most likely agree, and I thought what they were saying was true. However, his company actually made it possible. I wanted to tell everyone in Tokyo “Hey, IT IS POSSIBLE! This man showed it to me!”

H: No wonder they said it was impossible because it is really difficult, but actually they just gave up on that. However, we took the next step and tried thinking about reasons why paint doesn’t stay well. Later we found out it may be a result of the grease used during the polishing process. It brought us to mind that we needed to get the grease off the metal first. We started collecting various kinds of absorbent materials. Finally, we found the best solution.

S: Oh, I hope he is not giving too much Information…

H: This actually is from one horrible experience; A department store in Fukuoka had placed an order for 600 shelves with us before we noticed the problem.

S: I guess it scared you a lot!

H: I asked the supplier to get us all kinds of absorbent materials and we tried them all. We couldn’t rest at all until we found suitable materials, and finally we did and finished the 600 shelves.

After we overcame the grease issue, the next thing we needed to think about was color. We were reaching a best balance of blend. Thanks to the experiences with various kinds of requests, we are now able to get the picture for each order before we start working on them. However, there are still things that we’re not able to make possible, so we would like to work on them. Some pigment companies help us to create a new blend of pigments, too.

C: How did EXIT inspire you with business?

H: Shimizu is good at finishing metal works with a nice matte texture, and it is their original idea. That was one of the styles that we had been looking for before he brought it to Onojo.

S: Yes. People started calling it “EXIT finish”. It seems that nobody in Japan was able to do it, so people use our tiny products like hooks as a sample to show what they envision on a final product.

H: That’s true. I have been asked questions such as “Do you know the EXIT finish?” and “if possible, could you give us an estimate for that?” from other metal work companies. I had been applying similar kind of black leather touch as close as I could make it. At the time, Shimizu himself came over to visit our company and I was wondering if his EXIT could be that EXIT. After the visit, he requested a sample from us for his company. I was excited enough to call, “This is the original EXIT finish!”

The first thing I noticed from the original metal work was that the materials looked different. They pay a lot of attention to detail all the way to completion with the work they do, and the styles they use. Because of the metal work and styles used, they have a very original texture and look on their products, which is difficult to replicate. In my opinion, metal work factories/companies in Fukuoka are good at making something following someone else’s style. They are quick learners but have no expression because they were not trained as designers, so it’s a little difficult for them to suggest many stylish ideas.

C: How do you come up with new and interesting creative ideas of your own?

S: Most of our ideas come from our customers’ expectations, because most of them are fashion designers. These design ideas are made to suit items they have in their collection. Requests are usually left for us to design with a simple message; “We want something that fits our taste at this time.” Also, we have been able to meet great friends who work in the interior design industry, and they give us some great advice.

We had evolved over 10-15 years doing something like this. After we moved to Fukuoka and started collaborating with Tokiwa Tosou, we could complete what we had pursued. Before that, I wasn’t too thrilled with another company’s job, plus receiving some complaints from customers. I almost said, “This problem happens from coating, even though we did our best.” Instead, we sucked it up and gave apologies for it. We were frustrated, but persevered by painting ourselves. There was one setback though, we didn’t have enough equipment for bake coating. At the same time, I heard about Tokiwa Tosou.

C: Would you tell us your impression of Fukuoka after you actually started living here?

S: I think Fukuoka is very beautiful and has great food and cuisine as everyone says. I’ve only found one wrinkle; there are not many people who want to express their creative ideas. There are not enough galleries and museums for private exhibitions or works of modern art. I often wonder, “Why? Maybe, art and design are not fascinating enough to people here?” I don’t think Fukuoka is just another one of the local cities in Japan. I think Fukuoka is a remarkably historical and cultural city like Kyoto, but on the other hand, its subculture seems a bit immature.

For example, Los Angeles and San Francisco have their own subcultures, which are from their own musical styles and fashion, maybe from local shops and hotels. I have a desire to contribute to creating Fukuoka’s subculture. If someone, who is young and high spirited, tells me his/her good ideas, I am more than happy to give them a hand and some direction. I believe working little by little with individuals here eventually will make Fukuoka become as fantastic a city as Tokyo, but would be unlike the Tokyo culture. More people in the world would recognize this city, and admit “Fukuoka is cool.”

H: It seems Fukuoka has changed a lot, with the change of the flow of people in town. There is a project to try to make the Hakata-Tenjin area attractive enough that many people want to return.

S: Daimyo area used to be the center of attention, where a lot of people gathered from almost everywhere in Fukuoka and other prefectures in Kyushu, but recently it seems to be a little quiet. I have heard that there is a plan in progress to make Daimyo area like Omotesando in Tokyo, where there is a neighborhood with good atmosphere, a lot of trees, and a nice place to walk your dog. I think Fukuoka has a lot of capabilities and potentialities to be a new type of city. Keep an eye on how it is going to be for 5-10 years from now. I bet you Fukuoka will be a hot place filled with our cool products!

Kaoru Shimizu

Furniture designer, Metal worker

He was raised in the Shitamachi area of Tokyo, and started working at one of the metal factories there. Obtained some experiences from working at IDEE, and established EXIT METAL WORK SUPPLY with his work friends in 1996 in Tokyo. In 2012, he moved with his factory to Fukuoka.

http://www.exitmetalworksupply.com